GEAR Oil Additive for Triplex Mud Pumps

Newly machined gears often go through a phase of initial running-in wear due to metal to metal contact. In the case of heavily loaded gears also the oils are not able to provide the separating film between the tooth surfaces. Therefore the use of an additive that can provide a separating film or assist in plastic deformation helps. Molybdenum Disulfide with a natural affinity for metal is the best option due to its very high load handling characteristics.

TS-90 Moly Gear Concentrate (Additive) that can be used to newly machined or heavily loaded gears to minimise friction; reduce gear wear; protection during intermittent, extreme operating conditions; reduce gear noise levels and improve energy efficiency and prolong equipment life.

Issue:

During the initial mud pump “wear-in” period, it is common to see initial pitting on the tooth faces of Triplex Mud Pump gears.

Solution:

It is National Oilwell Varco’s recommendation to use a Molybdenum Disulfide oil addictive with the Mud Pump Oil during initial running and when signs of corrective (also known as “initial”) pitting are observed on Mud Pump gears. The oil addictive will help to polish the gear tooth surfaces and in some cases, if used in the initial Mud Pump “wear-in” period, can reduce the amount of initial pitting common Mud Pump gears.

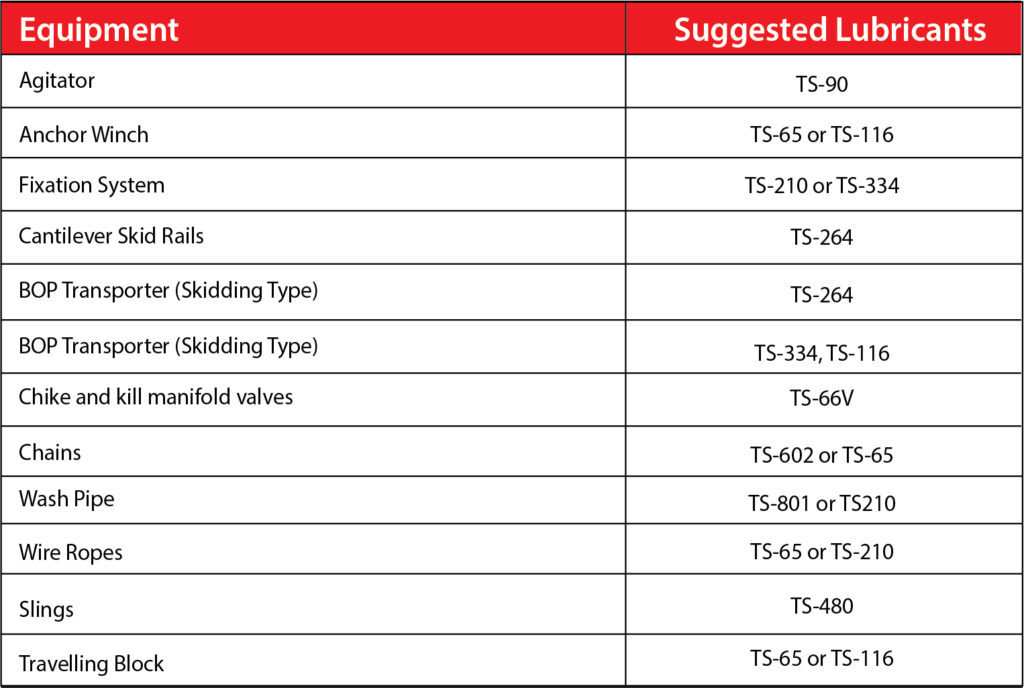

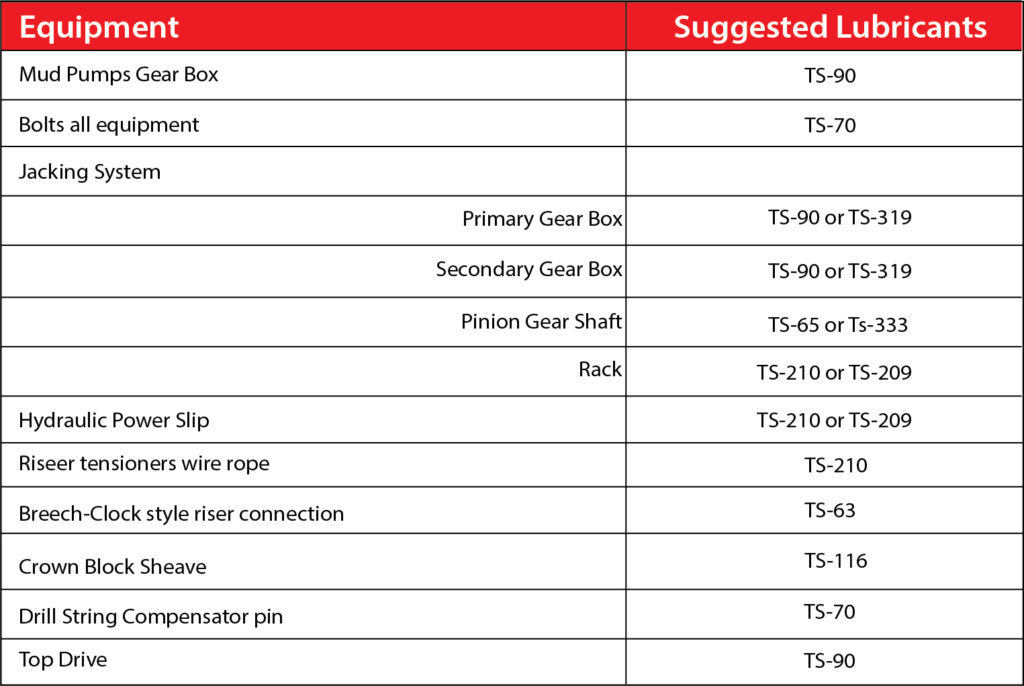

TS MOLY Application areas

Riser & BOP Bolts, Mud Pumps, Top Drives, Jacking System, Skidding, Gate Valves, Sheaves and Wire Ropes